Content:

Wire

Strip

Surface finish

Delivery tolerances

Wire

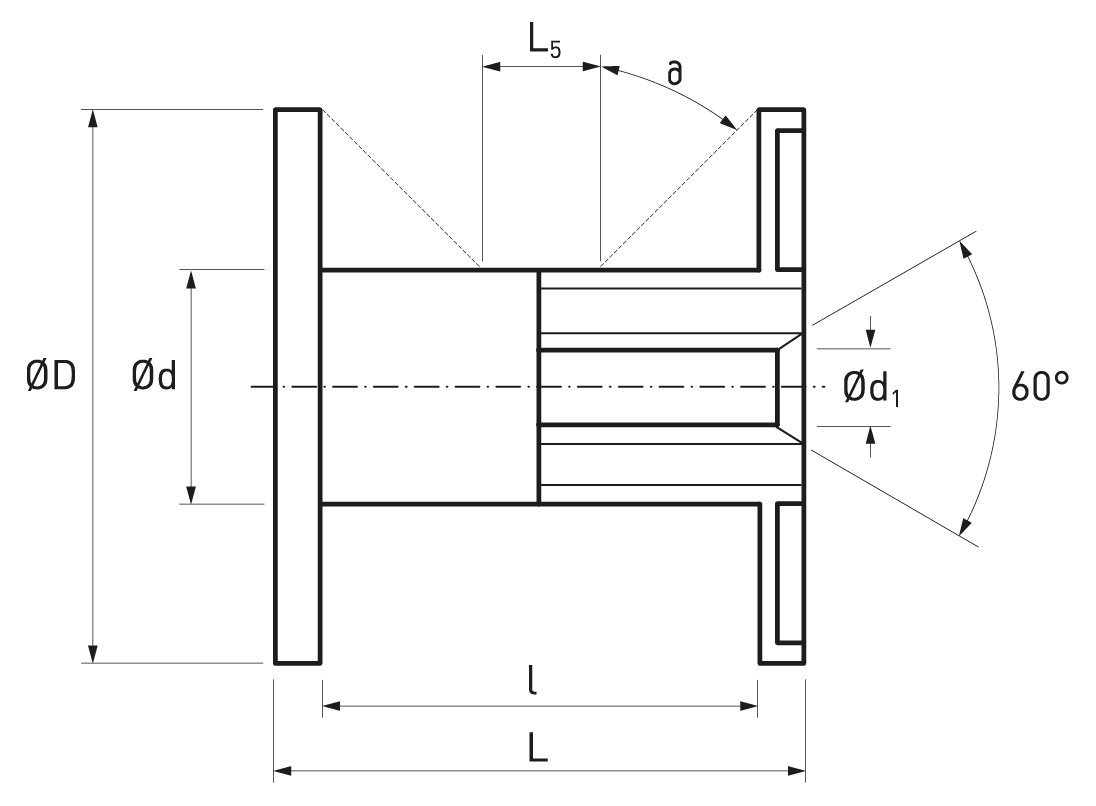

Wire with a diameter of ≤1.63 mm (0.064 in) is delivered on spools, as shown in the figure. Each spool contains a single continuous length of wire.

Wire with a diameter of ≤1.63 mm (0.064 in) is delivered on spools, as shown in the figure. Each spool contains a single continuous length of wire.

Wire sizes ranging from 0.40 mm to 1.63 mm (0.016–0.064 in) can also be supplied in round pail packs (drums), as shown in the table below.

Wire with a diameter greater than 1.65 mm (0.065 in) is typically supplied in coils with an inner diameter of approximately 500–600 mm (19.7–23.6 in).

Wire with a diameter of less than 1.82 mm can be supplied on standard spools. Each spool holds one continuous length of wire.

Types of wire spools

| Spool | Tare | Spool measurements | Wire diameter | Capacity approx. | ||||

| No. | g (lb) | D | D | D1 | L | L | mm (in) | kg (lb) |

| B 1 | 100 (0.22) |

75 (2.95) |

40 (1.57) |

16 (0.63) |

120 (4.72) |

100 (3.94) |

0.10 – 0.19 (0.004 – 0.007) |

1 (2.2) |

| B 2 | 115 (0.25) |

90 (3.54) |

40 (1.57) |

16 (0.63) |

120 (4.72) |

100 (3.94) |

0.20 – 0.24 (0.008 – 0.009) |

2 (4.4) |

| B 4 | 180 (0.40) |

120 (4.72) |

50 (1.97) |

16 (0.63) |

120 (4.72) |

100 (3.94) |

0.25 –1.00 (0.010 – 0.039) |

4 (8.8) |

| DIN 200 | 600 (1.32) |

200 (7.87) |

125 (4.92) |

36 (1.42) |

200 (7.87) |

160 (6.30) |

0.16 –1.20 (0.006 – 0.047) |

10 (22.0) |

| DIN 250 | 1,050 (2.31) |

250 (9.84) |

160 (6.30) |

36 (1.42) |

200 (7.87) |

160 (6.30) |

0.30 –1.63 (0.012 – 0.064) |

20 (44.1) |

| DIN 355 | 1,850 (4.08) |

355 (13.98) |

224 (8.82) |

36 (1.42) |

200 (7.87) |

160 (6.30) |

0.50 –1.63 (0.022 – 0.064) |

40 (88.2) |

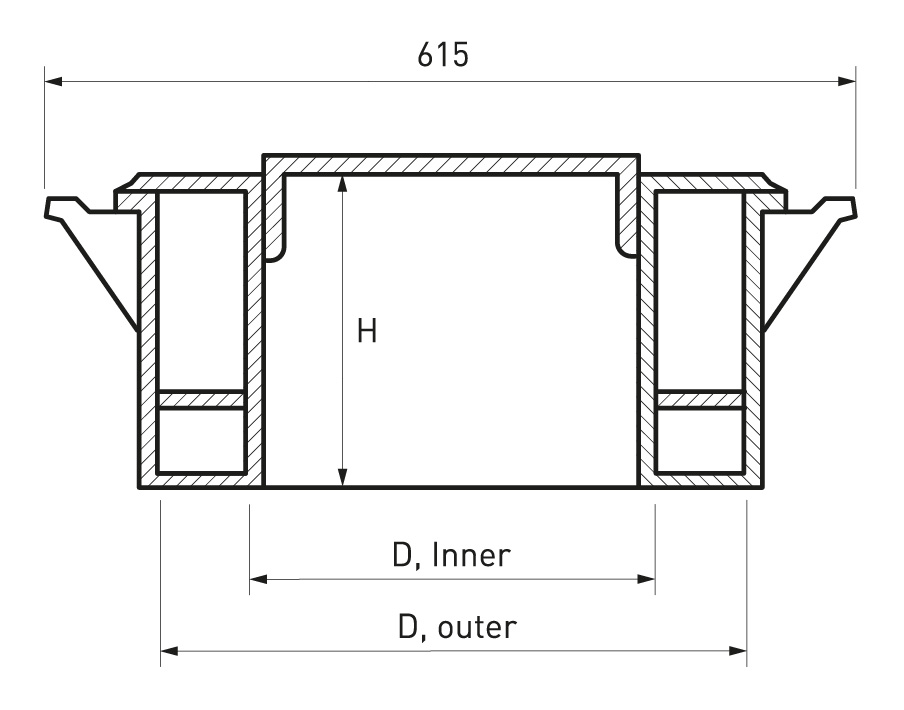

Type of wire pails (drum pack)

| Pail | Tare | Pail Measurements, mm (in) | Material | Wire diameter | Capacity approx. | ||

| No. | g (lb) | D, Outer | D, Inner | Height | mm (in) | kg (lb) | |

| P 50 | 2,600 (5.7) |

508 (20.0) |

330 (13.0) |

150 (5.9) |

plastic | 0.40 –1.63 (0.016 – 0.064) |

33 (73) |

| P 100 | 3,500 (7.7) |

508 (20.0) |

330 (13.0) |

250 (9.8) |

plastic | 0.40 –1.63 (0.016 – 0.064) |

50 (110) |

| P 200 | 8,500 (18.7) |

500 (19.7) |

300 (11.8) |

520 (20.5) |

cardboard | 0.80 –1.63 (0.031 – 0.064) |

160 –240 (352 – 529) |

| P 350 | 10,000 (22.0) |

500 (19.7) |

300 (11.8) |

820 (32.3) |

cardboard | 0.80 –1.63 (0.031 – 0.064) |

250 –400 (551 – 882) |

Strip

Available in coils with an internal diameter of approximately 400 mm (15.7 in). The lengths specified in the table are typically supplied, though larger coils are available upon request.

Strip length

| Strip thickness | Length (approx.) | ||||

| Kanthal® | Nikrothal® | ||||

| mm | in | m | ft | m | ft |

| 3.0 | 0.12 | 65 | 213 | 90 | 295 |

| 2.5 | 0.10 | 80 | 262 | 105 | 344 |

| 2.0 | 0.08 | 100 | 327 | 130 | 425 |

| 1.5 | 0.06 | 135 | 442 | 175 | 573 |

| 1.0 | 0.04 | 200 | 655 | 260 | 851 |

| 0.5 | 0.02 | 400 | 1,309 | 500 | 1,636 |

Surface finish

Element materials are available with the following surface finishes. Some finishes may not be available in certain markets. For full details, please contact your local supplier.

Forms of surface finish

| Quality | Bright annealed | Oxidized annealed | Pickled | Grinded | ||||

| mm | in | mm | in | mm | in | mm | in | |

| Kanthal® A-1 Wire | <2.3 | <0.090 | ≥1.02 | ≥0.040 | >5.01 | ≥0.197 | – | – |

| Kanthal® A-1 Strip | ≥0.1 - 3.0 | ≥0.003 - 0.118 | ≥0.1 - 3.0 | ≥0.003 - 0.118 | – | – | ≥0.1 - 3.0 | ≥0.003 - 0.118 |

| Kanthal® AF Wire | <2.3 | <0.090 | ≥1.02 | ≥0.040 | >5.01 | ≥0.197 | – | – |

| Kanthal® AF Strip | ≥0.1 - 3.0 | ≥0.003 - 0.118 | ≥0.1 - 3.0 | ≥0.003 - 0.118 | – | – | ≥0.1 - 3.0 | ≥0.003 - 0.118 |

| Kanthal® D Wire | <2.3 | <0.090 | ≥1.02 | ≥0.040 | >5.01 | ≥0.197 | – | – |

| Kanthal® D Strip | ≥0.1 - 3.0 | ≥0.003 - 0.118 | ≥0.1 - 3.0 | ≥0.003 - 0.118 | – | – | ≥0.1 - 3.0 | ≥0.003 - 0.118 |

| Alkrothal® Wire | <2.3 | <0.090 | ≥1.02 | ≥0.040 | >5.01 | ≥0.197 | – | – |

| Alkrothal® Strip | ≥0.1 - 3.0 | ≥0.003 - 0.118 | ≥0.1 - 3.0 | ≥0.003 - 0.118 | – | – | ≥0.1 - 3.0 | ≥0.003 - 0.118 |

| Nikrothal® 80 Wire | <5.0 | <0.196 | ≥1.02 | ≥0.040 | >5.01 | ≥0.197 | – | – |

| Nikrothal® 80 Strip | ≥0.1 - 3.0 | ≥0.003 - 0.118 | ≥0.1 - 3.0 | ≥0.003 - 0.118 | – | – | ≥0.1 - 3.0 | ≥0.003 - 0.118 |

| Nikrothal® 60 Wire | <5.0 | <0.196 | ≥1.02 | ≥0.040 | >5.01 | ≥0.197 | – | – |

| Nikrothal® 60 Strip | ≥0.1 - 3.0 | ≥0.003 - 0.118 | ≥0.1 - 3.0 | ≥0.003 - 0.118 | – | – | ≥0.1 - 3.0 | ≥0.003 - 0.118 |

| Nikrothal® 40 Wire | <5.0 | <0.196 | ≥1.02 | ≥0.040 | >5.01 | ≥0.197 | – | – |

| Nikrothal® 40 Strip | ≥0.1 - 3.0 | ≥0.003 - 0.118 | ≥0.1 - 3.0 | ≥0.003 - 0.118 | – | – | ≥0.1 - 3.0 | ≥0.003 - 0.118 |

Delivery tolerances

Cold-drawn round wire is supplied with a resistance tolerance of ±5% per length. Cold-rolled strip is also supplied with a resistance tolerance of ±5% per length. Wire and strip can be supplied with closer tolerances upon request.

Important

Tolerances on dimensions and resistance per unit length must not be specified simultaneously.